The COVID19 crisis and the ensuing lockdown and physical proximity aspects have closed down primary modes of education which involved kids going to a class room and a teacher leading them on to learning. After the lockdown, privileged communities had not much of a problem shifting to digital technologies simply because of a history of access. This however created a huge divide, because a majority of learning population in India are underprivileged. We have already lost a lot of time in coming to here that we think about access to technology for the underprivilaged, but lets see what we can do from here on.

Thanks to the conversations with the Door Step School, a school-on-wheels NGO that has been doing pioneering work among the slums and low-income housing settlements in Mumbai and Pune, the obvious struck me, we need computers! Low cost and quick. Here are the options we have in front of us:

- Rescue old computers from companies and homes and remake them with adequate low-resources friendly software based on opensource Linux platforms and pass them off to the NGO. Although Pune is one of the IT hubs of india, a message of this kind on LinkedIn didn’t get much response so far. Maybe because i suck at communication or maybe people i know in my network are not really into IT or that people are frugal and only using what they have so there’s no computer to spare.

- A smartphone could be used as a very powerful computer. However, it has the advantages and limitations:

- Advantages:

- A very powerful computer!

- All communiations built in – wifi, bluetooth, 4g, etc.

- Has mic, speaker, camera – all inbuilt – for any kind of online classes.

- Could be used as a standalone educational device without any external devices. This is the way privileged students currently use as a primary mode of study i guess (no ref here, its an assumption from my student’s pool).

- Disadvantages:

- Costly – A decent one could start from 8k onwards. But if using parent’s ones, the amount of time a parent would lend her/his device will be questionable because the parent might need it themselves.

- Small screen. But that can be augmented by using Chromecast (1st generation for about 700 Rs) or Miracast or AnyCast devices and connected to a HDMI friendly TV or monitor.

- Lack of keyboard mouse – This can be solved by using bluetooth keyboard and mouse (~1.4k Rs.)

- Lack of access ports for USB pendrives and such – One can buy some cheap connected of the market.

- High distractability – A mobile device is usually plugged into various communication services – calls, sms, social media and so on. This makes this device not so much suited for focus requiring educational work, unless a very high level of self discipline is acquired.

- Advantages:

- A dedicated computer using modern low-cost microcomputers such as the Raspberry Pi.

This last option seems very interesting. Looking at availability and cost, the following configuration works fine for me.

| Components | Cost (INR) |

| Raspberry Pi 3B + case + fan | 3000 |

| 16GB memory card | 350 |

| Keyboard + mouse (wired) | 450 |

| Raspberry Pi power supply | 500 |

| Speaker | 500 |

| USB camera | 650 |

| HDMI cable | 150 |

| Projector mini with speaker* | 6000 |

| Total for basic computer | 11600 |

One can go lower than above, by replacing Raspberry Pi 3B with Raspberry Pi Zero W, but then its only 1k of saving. Another avenue is to replace the 6k projector with a 4.5k LCD.

Connect it with any wifi network (from a smartphone) and everything is just like a desktop. Raspberry Pi can be loaded with Raspbian OS, a version of Debian OS systems. This comes with the fantastic LibreOffice system of word writer, spreadsheets, powerpoint equivalents. It also comes preloaded with programming tools and Python is just a marvel to learn on this platform. One can also program in C or Java. It has Wolfram mathematical tools. One can also make a small para-legal community radio with it (50m radius range), without additional cost!

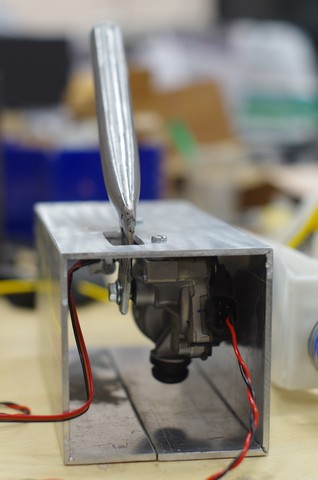

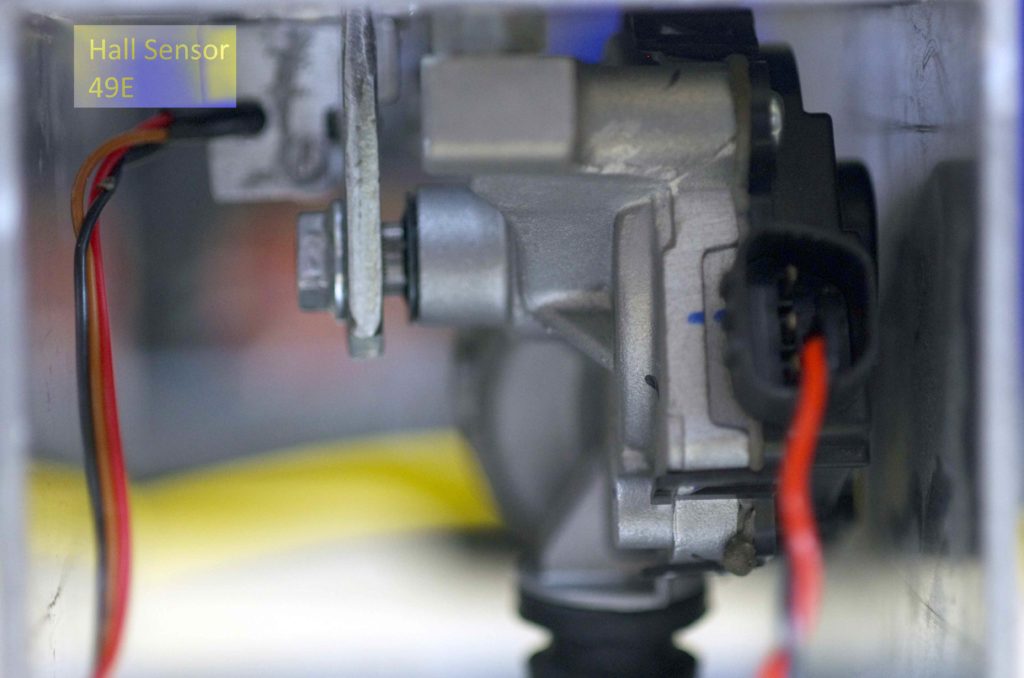

But one of the biggest advantages of this RPi platform is the huge huge community around it that can help you immensely. There are plenty of projects and possibilities of using this small computer for any number of modern applications. IoT, communication, interfacing sensors, etc. I personally use it for my SmallDAC series of low cost industrial/scientific controllers. Interesting to note that Raspberry Pi was developed as an aid to school kids in the UK to become digital age friendly. Maybe we can leverage all this goodness for our cause. Here’s some context.

I am in love with the Raspberry Pi and will be happy to help others make this small computer. Currently, I have assembled this kit and am awaiting to demo it in one of Door Step School’s centers. Lets see how suitable it is, or not.