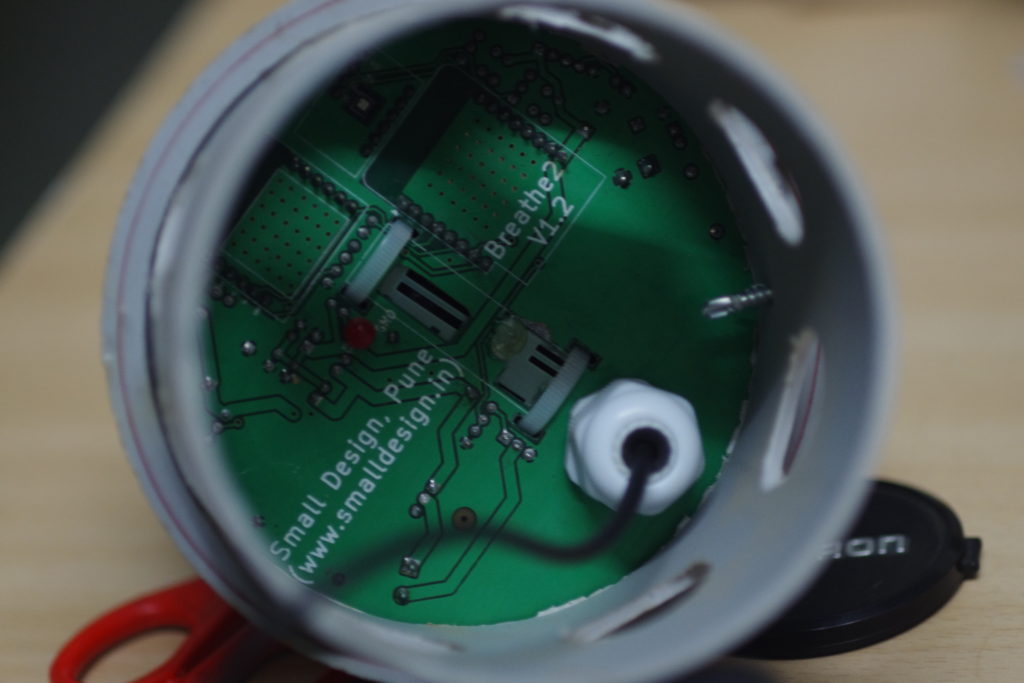

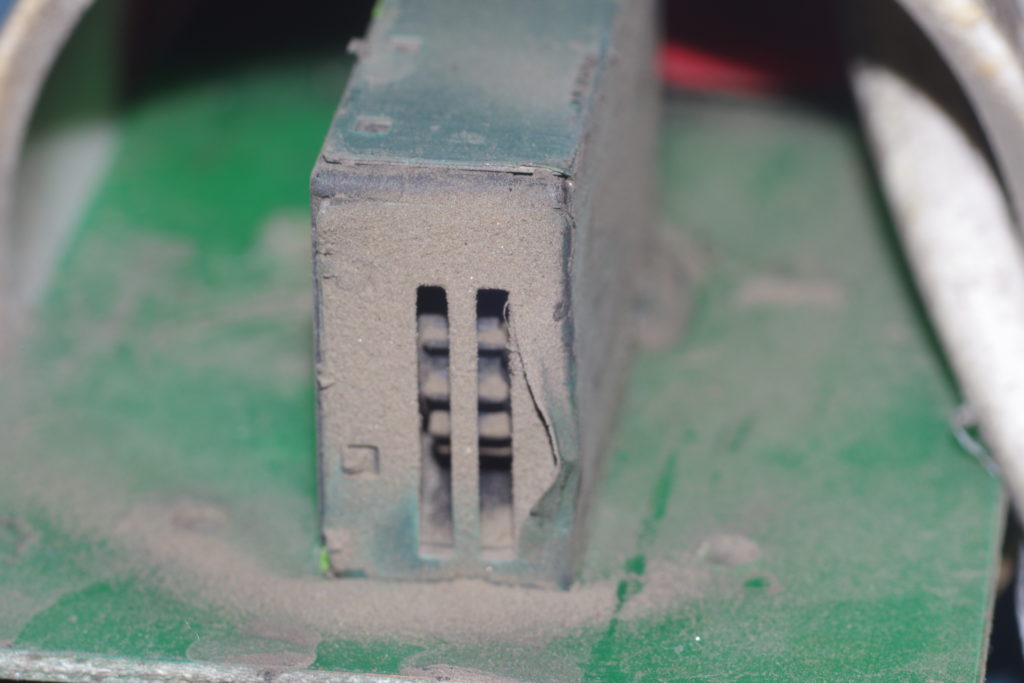

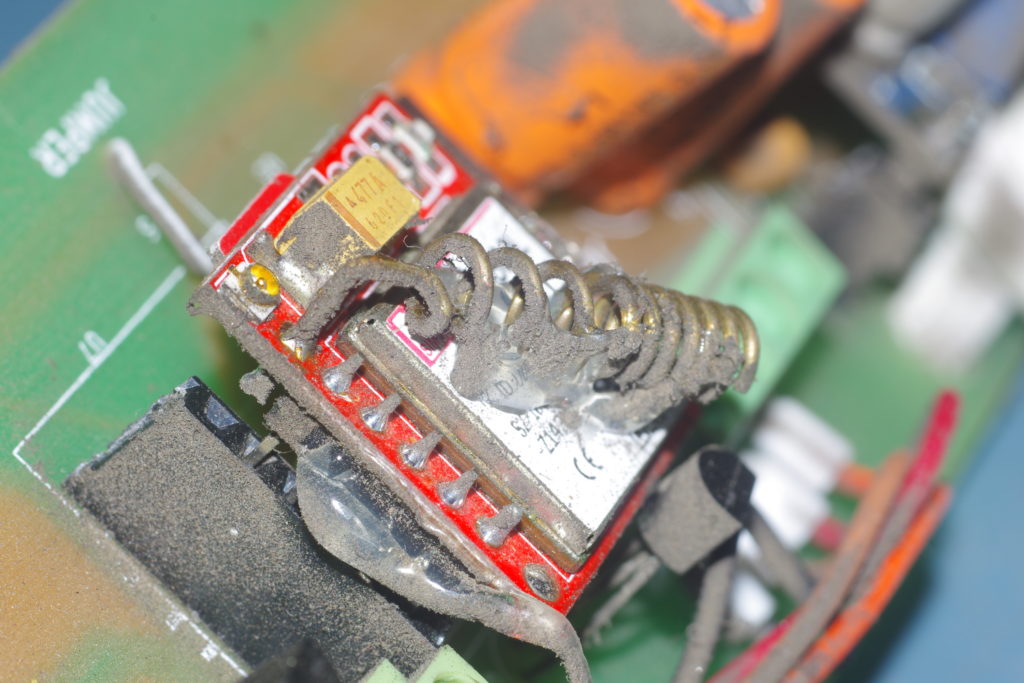

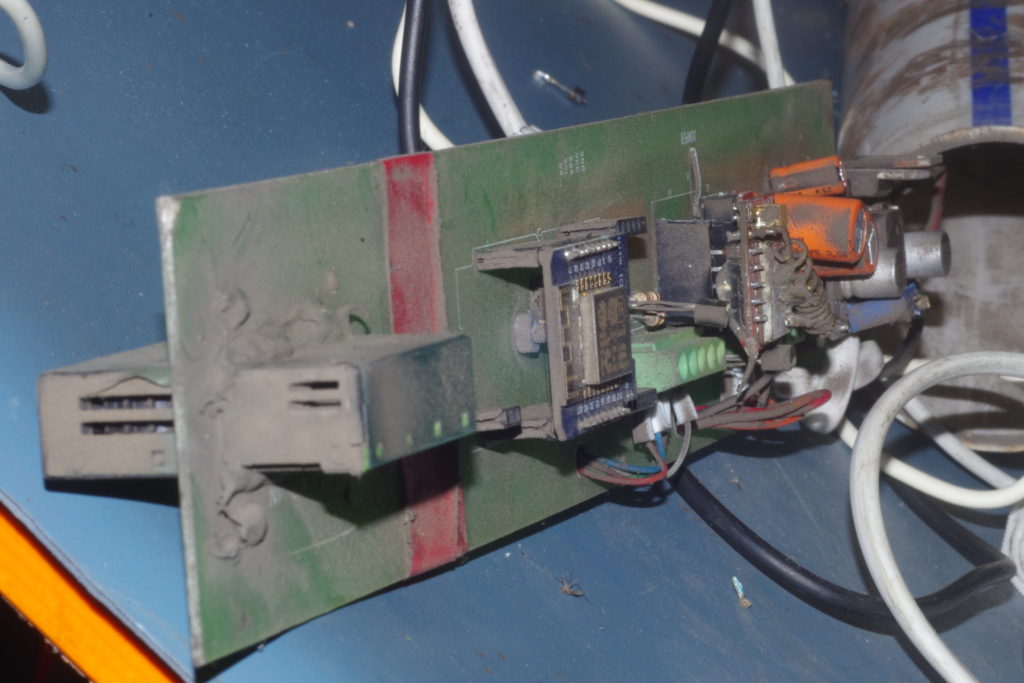

After months of exposure to Shivajinagar’s traffic and running on a 12V fan 24×7 (or whenever the mood was not bad), here’s the dust settlement on the original version’s innards.

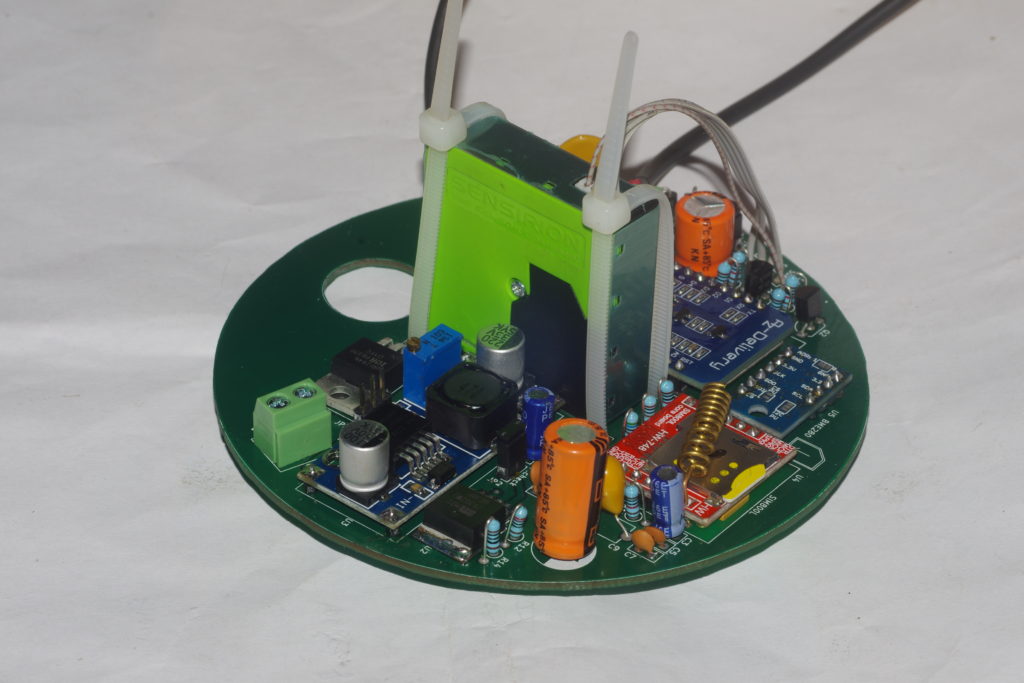

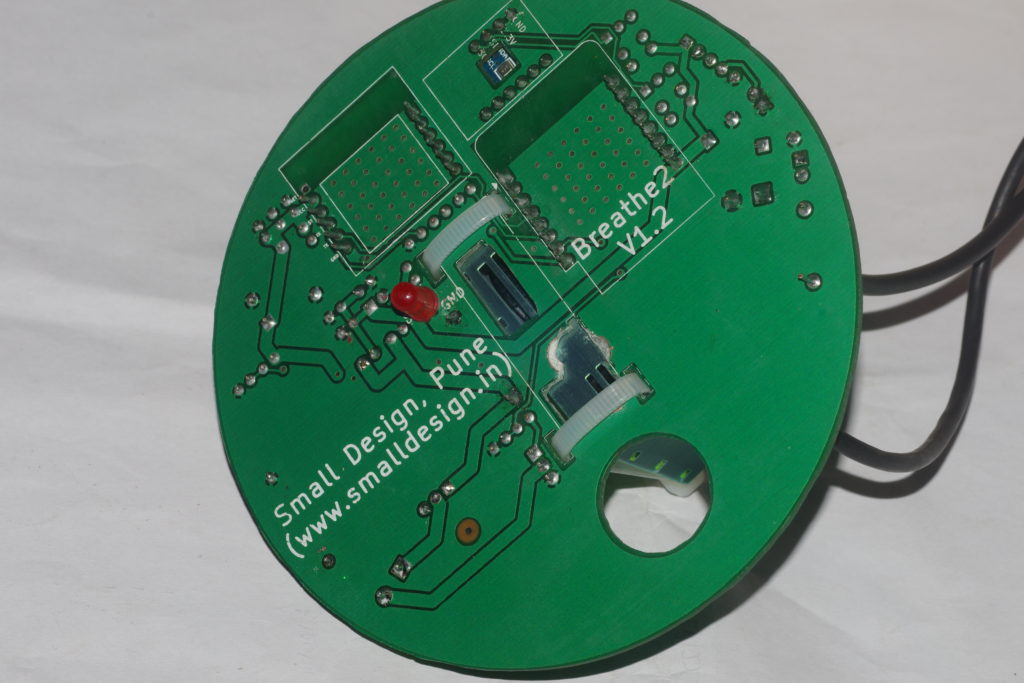

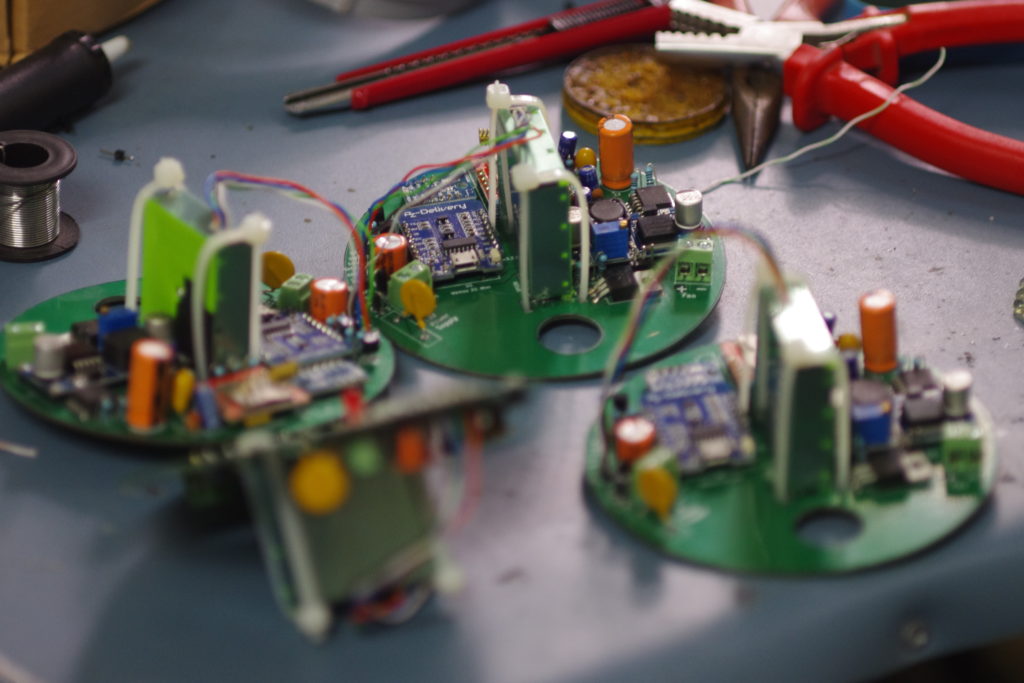

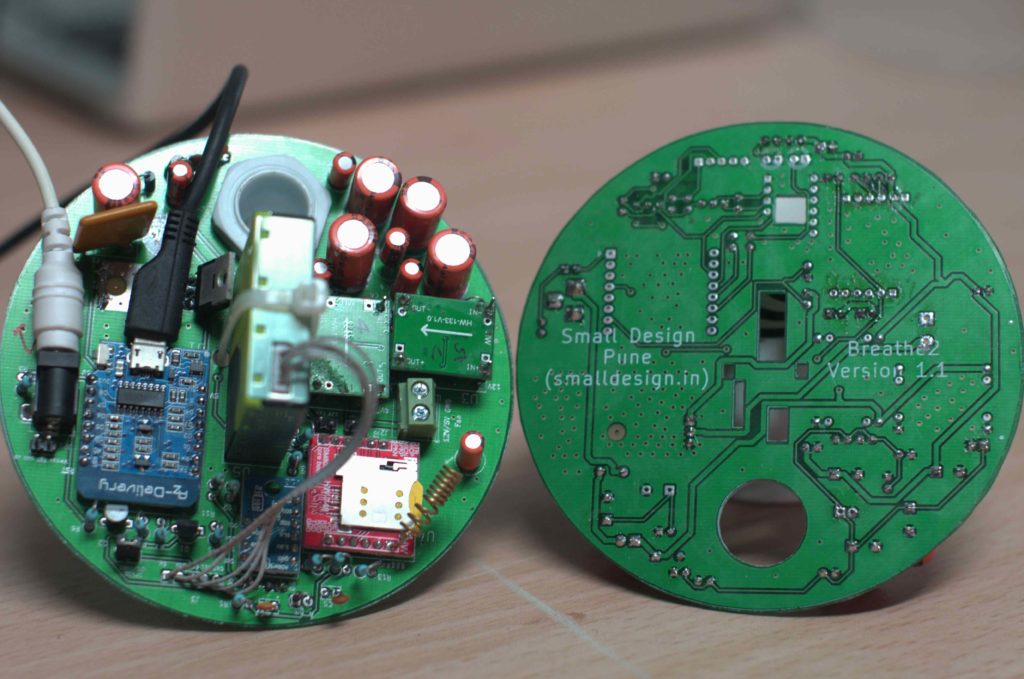

So it proves that this design is bad at the fundamental level. This amount of dust, and expected condensation will definitely cause some shorting someday. The newest design Breathe2 V1.2 bypasses this condition by shielding the external environment from the components. Only the underside of the PCB (where there are no components except a LED) is exposed.