Category: Mask Testing Device

Mask Testing Device

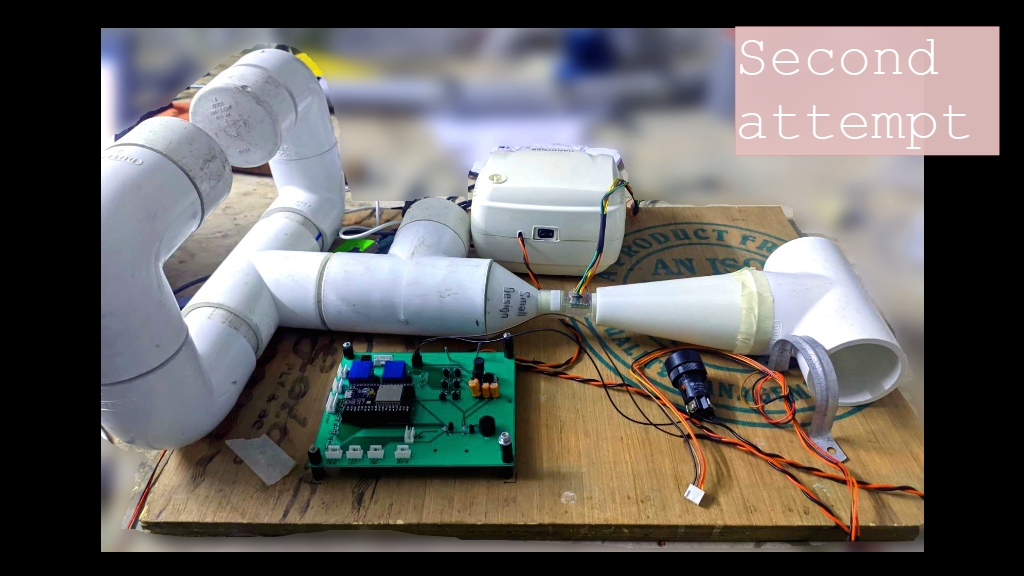

V0.1 and V0.2

Some frugal ideas

Open-hardware Mask Testing Device – the proposal

A proposal for funding by engineers of the India COVID SoS volunteer network.

Updates – 21st Oct. 21.

Approved for funding by Give Back Foundation, USA. Awaiting process.

Host organizations – Anubhav Prathisthan, Karjat, MH, India & Vigyan Ashram, Pune, MH, India.

The last year has seen a proliferation of manufacturing, innovation, import and small scale production of various kinds of masks, from medical grade surgical, disposable FFP2 and equivalent to reusable versions using a variety of materials and manufacturing methods. A recently released report from a large scale study carried out in Bangladesh clearly shows that masks are effective in reducing COVID spread but that the reduction is also based on the types and materials of the masks themselves. In the absence of broad regulatory standards, it is difficult for healthcare providers, relief organizations, NGOs and the public in general to know if the masks they are using meet the minimum requirements for infection prevention. Given the effectiveness of universal masking in reducing transmission rates for a variety of pathogens, we feel access to mask testing is a critical need, especially in the global south where this infrastructure remains lacking. In India, there seems to be no publicly accessible mask testing service. Similar needs can be seen in many other developing countries. Often masks have to be sent to the US or the EU to get tested.

In Phase 1, we propose to make an opensource and open-hardware face mask quality testing device.

In Phase 2, we want to develop a testing protocol and try it out with 3-4 NGOs in India or elsewhere.

Currently, we are seeking funds for Phase 1 only.

Why another method / What’s new?

Around the world, there are a variety of professional lab-based setups and amateur setups to test masks for the public (see a non-exhaustive comparison table here). However, these are often geographically far from the global south and operate with varying levels of sophisticated equipment needing trained people to operate and interpret. Often amateur setups provide only qualitative testing. In short, either they are relatively inaccessible or inadequate for local testing needs. Currently local testing does not take place in much of the global south.

We want to make a portable, compact, high shelf-life, easy and minimal interface mask testing device with testing for 3 key parameters of particulate filtration efficiency (<PM0.5), breathability (pressure drop) and fit (qualitative). It is intended to be used by minimally trained technicians or amateurs on field sites in non-lab settings. The device cost is to be kept low and its design to be open sourced for replication and improvements. We want to develop an appropriate testing protocol.

What is the use-case and dissemination scenario for this device?

It is envisioned as a made-to-order device catering to the needs of NGOs in a country (whoever can afford and staff it) along with being a template device intended to be replicable in other parts of the world by the maker community. We don’t intend to make a certified and calibrated unit as that would significantly increase the challenges, budget and time delays. Instead, this device will be operated as a citizen science unit expecting discretion by the users and consumers of the device’s outcomes.

Device target features

- Simple interface, designed for ease of use by non professionals, compact housing to enable portability, storage, dust resistance.

- User interface should indicate – Particulate Filtration Efficiency (PFE) and pressure drop / breathability, and probably results of a fit test.

- Use standard components to enable replication by the global maker community. This may reduce calibration uncertainty across devices.

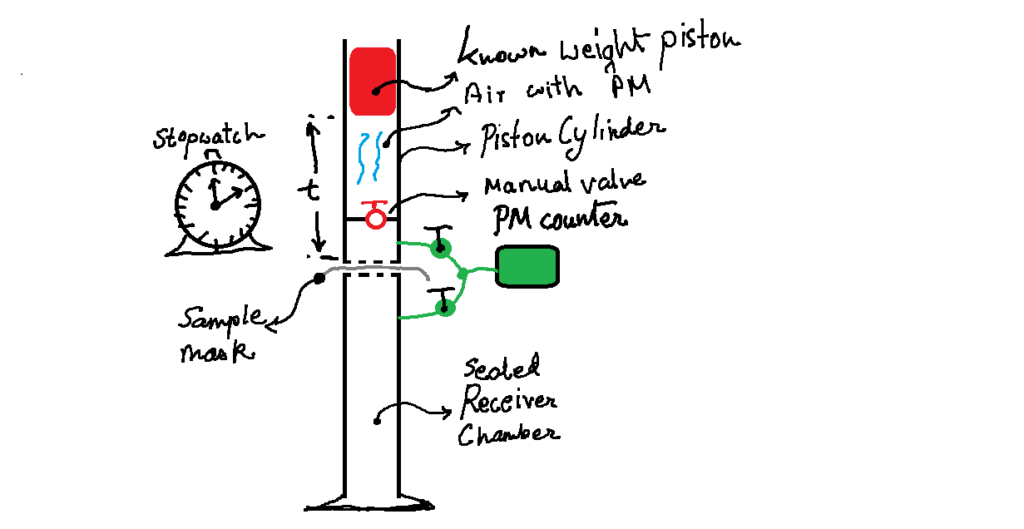

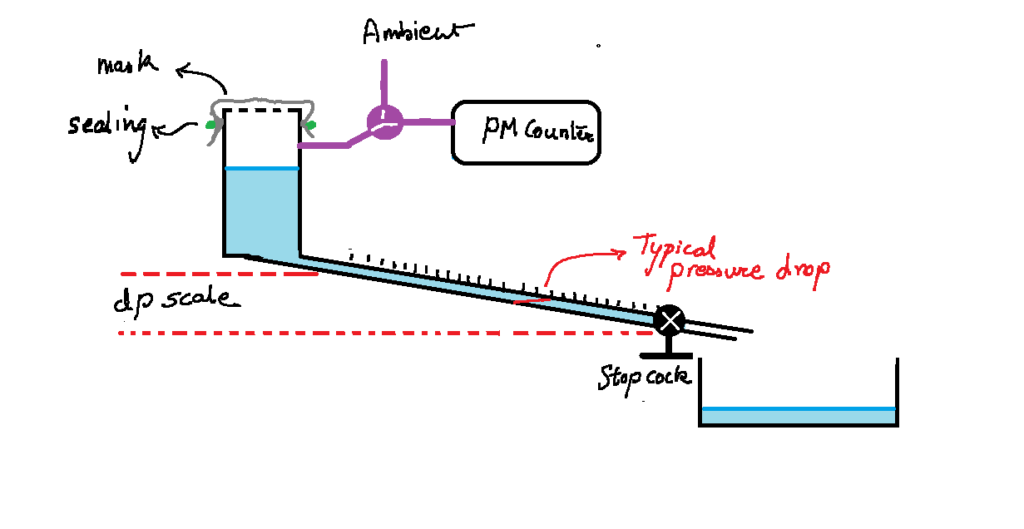

Proposed device – hardware

Figure 1 : Outline of the device

The main idea is to make an instrumentation box with a human interface (screens and buttons) equipped with 2 interfaces for carrying the following types of tests. The box could be placed in a closed and sealed room for the sake of experimentation.

- Direct testing – If the desire is to test the performance of a mask while it is being worn by a person, a sampling tube could sample the air near the mouth after and before the mask to give out PM difference as well as pressure drop characteristics as per inhalation and exhalation. Such results comment on all the 3 parameters – breathability, PFE and fit.

- Mask media testing – If the desire is to test only the mask media, a sample mask can be placed in between an air-tight jig and ambient chamber air containing PM particles could be drawn through it. The PM concentration before and after the mask as well as the pressure drop can be measured indicating the quantitative PFE as well as breathability of the sample.

Hardware components and roles

- PM sensors – These will be required to measure the PM concentrations before and after the mask. Commonly available PM2.5 monitoring devices can be used to approximate PFE.

- Absolute air pressure sensors could be used to measure the pressure drop across the mask, in order to figure out the breathability of the test materials.

- Air flow sensor – needed to measure and control (as a feedback) the air flow being generated in order to simulate breathing inhalation flow rates.

- Suction fans – needed to simulate either high breathing conditions when carrying out a media test on a media test setup, or for sampling of air from the air gap between the nose and the mask for doing the combined (fit+breathability+PFE) test on a person wearing the mask.

- PM source of particulate matter (PM) could be a medical nebulizer with common salt water as PM material. The source could be controlled on/off as per the measured ambient PM and to maintain a steady value. Some heaters need to be used downstream to aid aerosol formation.

- Control and human interface – A microcontroller or microcomputer could operate the tests as per a set algorithm as well as provide an interactive display with required data.

Project Budget (Phase 1)

Each device can cost somewhere between INR 40-56k or USD 520-750, depending on the sophistication of controllers, interfaces and features. See the components list here. Taking a conservative estimate here is the overall project breakup.

| Task | Cost (USD) | |

| 1 | Cost of 3 working prototypes to be manufactured. | 2,300 |

| 2 | Development materials, test benches, consumable costs, etc | 1000 |

| 3 | Human resource costs for the remuneration of 4-5 engineers/researchers | 2500 |

| 4 | Testing of 1 prototype with standard test equipment in the US/EU | 1000 |

| 5 | Institutional overheads | 700 |

| Total | 7500 USD |

The funds will be held by a non-profit NGO – Anubhav Prathisthan Trust based in Karjat, near Mumbai, India. The host organization will be another non-profit NGO – Vigyan Ashram, based in the city of Pune. The work will be carried out and directed by Subir Bhaduri, in his workshop Pune, in collaboration with the host organizations and the team of mentors and volunteers.

Tentative project workflow (Phase 1)

# | Task | Weeks (total 3 months) | |||||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | ||

| 1 | Brainstorm & freeze design V1 | X | X | ||||||||||

| 2 | Get off-the-shelf components | X | X | X | |||||||||

| 3 | Get custom made components | X | |||||||||||

| 4 | Assemble and code | X | X | X | |||||||||

| 5 | Develop testing method | X | X | X | |||||||||

| 6 | First testing | X | X | ||||||||||

| 7 | Review of design – V2 | X | X | ||||||||||

| 8 | Order and get components | X | X | ||||||||||

| 9 | Assemble V2 | X | |||||||||||

| 10 | Testing V2 | X | X | X | |||||||||

| 11 | Send V2 to field testing | X | X | ||||||||||

| 12 | Make modified design – V3 | X | X | X | |||||||||

| 13 | Order components for 3x devices | X | X | ||||||||||

| 14 | Assemble 3x devices of V3 design | X | X | ||||||||||

| 15 | Field testing of 3x devices | X | X | X | |||||||||

| 16 | Documentation and closure report | X |

Deliverables (Phase 1)

- 3x working prototypes

- Online documentation of designs, CAD files, source code of firmwares, etc.

- Documentation for making open-hardware mask testing device

Team and tasks

Since we all are working remotely as well as locally, the overall project is divided as per tasks and owners who will be responsible for those tasks. The remuneration is discussed accordingly. See table here. The project leader is Subir Bhaduri, a freelancer with active interest in social technology development and also an active member in the India COVID SoS group.

- Mentors, as listed below are subject experts in mask testing methods worldwide. We have vetted our designs and approach with this group of experts and will be engaging with them as the project proceeds.

- Aaron Collins – Youtuber who has tested a lot of masks for various organizations and people and transparently shared the results, concerns and design features over the past 2 years.

- Matthias Schibli works at Sensirion, and has a lot of experience with low cost sensors. He is also developing a low cost mask testing device.

- Timothy Sipkens is with the National Research Council of Canada and has carried out various works in mask testing and design.

- Rebecca Lau is with MakerMasks.org and has been actively supporting the IndiaCOVIDSoS team to implement mask designs for the general public.

- Steven Rogak is with the University of British Columbia and has significant experience in filtration tests and mask design in general. He has also been working with his student Thomas Bement (UBC) on a similar frugal mask testing device.

- Stephen Salter is the president of Farallon Consultants Limited, providing environmental consultancy to communities and companies. He has been actively pushing for adoption of cloth masks for the general public.

- Asit K. Mishra is a scientist working in indoor air quality and has been helping out in determining masking and ventilation areas within IndiaCOVIDSoS network.

- Engineering – This team will actually build the devices.

- Subir Bhaduri is a freelance engineer with a workshop/lab located in Pune, India.

- Newly recruited engineers for this project

- Vigyan Ashram students and faculty.

- Online research – This team will carry out tasks possible online from remote locations, such as documentation, research, communications, etc.

- Garima Suneja is a bioscientist/environmental biologist based out of Bangalore, India. She has been an active part of the masks, risk prevention and engineering teams within IndiaCOVIDSoS network.

- Shruti Mankar is a bioengineer based in Kobe, Japan. She has been leading the mask team in IndiaCOVIDSoS.

- Aditi Joshi is an active on-the-ground member of the IndiaCOVIDSoS based out of Mumbai, India. She has been directing the masks and risk mitigation groups towards the right questions and gaps.

- Abhigyan Ray is a chemical engineer and currently a graduate student at ICT, Mumbai, India. Vercy active on the IndiaCOVIDSoS network.

- Testing partners –

- JSS, Bilaspur, India is an NGO devoted to developing a low-cost and effective health program that provides both preventive and curative services in the tribal and rural areas of Bilaspur and surrounding areas of Chhattisgarh in central India.

- Other NGOs needing mask testing services.

Disclaimers / notes

- The device is not intended to be a scientific instrument. It is meant to be a basic mask quality testing device for the purpose of on field evaluation of mask samples.

- The design is going to evolve as per discoveries of the team on sensor availability, dynamic ranges, sensor types and technologies, testing feedback, etc.

- Various approximations will be used to give out tangible test results, to cover for the lack of sophisticated and affordable testing methods.

- The device design is intended as a starting base for future development by interested groups worldwide.

- A testing scheme will be used to compare this device to standard testing procedures practiced in the US/EU by mentors available within the team.