( Developed at Small Design, Pune India. Development partly funded and supported by Vigyan Ashram, Pabal, India)

Abstract

A novel incineration device has been developed that uses a separate pyrolysis stage to decompose used sanitary napkins into hydrocarbon vapors and combustible gases along with some non-combustible gases and char. These vapors and gases are made to pass over a high temperature zone, created by electric coils (>500 degC) where they autoignite in the presence of oxygen. The heat from the flames partially drives the pyrolysis of remaining sanitary pads. A smoke stack thermocouple sensor feeds back values to a PID controller implemented through a microcontroller to maintain proper pyrolysis and combustion conditions. At the current stage of development visible smoke has been reduced drastically compared to conventional small incinerators. Further studies in flue gas composition, combustion efficiency, etc are to be carried out.

Background

Sanitary napkin incinerators are widely available and can also be bought online in India (eg.). The products range from sizes suitable for personal home use to large sizes for use in institutions, hotels, offices, etc. These consist of an insulated chamber within which there is an electric coil. The sanitary pads are dropped into a chamber which is heated to high temperatures in the presence of forced or natural air draft. The high temperatures ignite the sanitary pads (which are made of polymers materials) and the fumes are carried out of the setup through a chimney.

The problem here is that the designs often do not ensure that the fumes from the sanitary pads catch fire and large pockets of unburnt hydrocarbon (from the polymers) gases are emitted as white smoke. Proper combustion requires three things: Right temperature, proper fuel and oxygen mixture (near stoichiometric or lean) and time for combustion reactions to complete. The existing designs fail to stop generate smoke during the following conditions:

- The sanitary napkins essentially contain bodily fluids and hence are contain water. If a direct flame is exposed to such a water soaked material, the surfaces immediate to the heat source will dry first, pyrolyse and if temperatures are right, catch fire. This is turn will dry the underlying material. However, pyrolysis begins non uniformly whereas due to the presence of water the temperatures near these surfaces are too low to allow combustion reactions to occur. As a consequence some pyrolysis vapors and gases escape as visible white smoke even if surrounding areas are in flames.

- Even with a forced draft which ensures presence of sufficient oxygen, the current product designs do not ensure that every parcel of gas in the chamber while on the way out to the chimney passes through high temperatures (at least above autoignition temperatures) AND has the right fuel-oxygen mixture, thus resulting in smoke. The smoke from such incomplete combustion is mostly white or brown in color and may contain high amounts poisonous carbon monoxide and toxic hydrocarbons such as furans and dioxins. Although the chimney helps transport the gases away from end users, it nevertheless pollutes the environment and may also affect nearby rooms or people living/working around the incinerator area.

The necessary way

To improve the above issues in the existing designs, the following process is being developed:

- A drying stage needs to be implemented where the temperatures are near 120-200 deg C in the chamber containing the sanitary napkins. Note that pyrolysis reactions start above 300 deg C.

- After sufficient drying, pyrolysis temperatures of above 300 deg C need to be achieved in the chamber. The exiting pyrolysis fumes would then contain various amounts of water vapor, CO2, CO, and various hydrocarbons along with fumes of degrading bodily fluids (proteins) (refs).

- These gases and vapors must pass over a high temperature zone above the autoignition where they combine with air inflow to develop flames.

- The heat released from such flames must be able to drive the pyrolysis and sustain the process till the complete charring of sanitary napkins within the chamber.

These process are combined into a compact thermally insulated product which is controlled by a microcontroller system.

Implementation

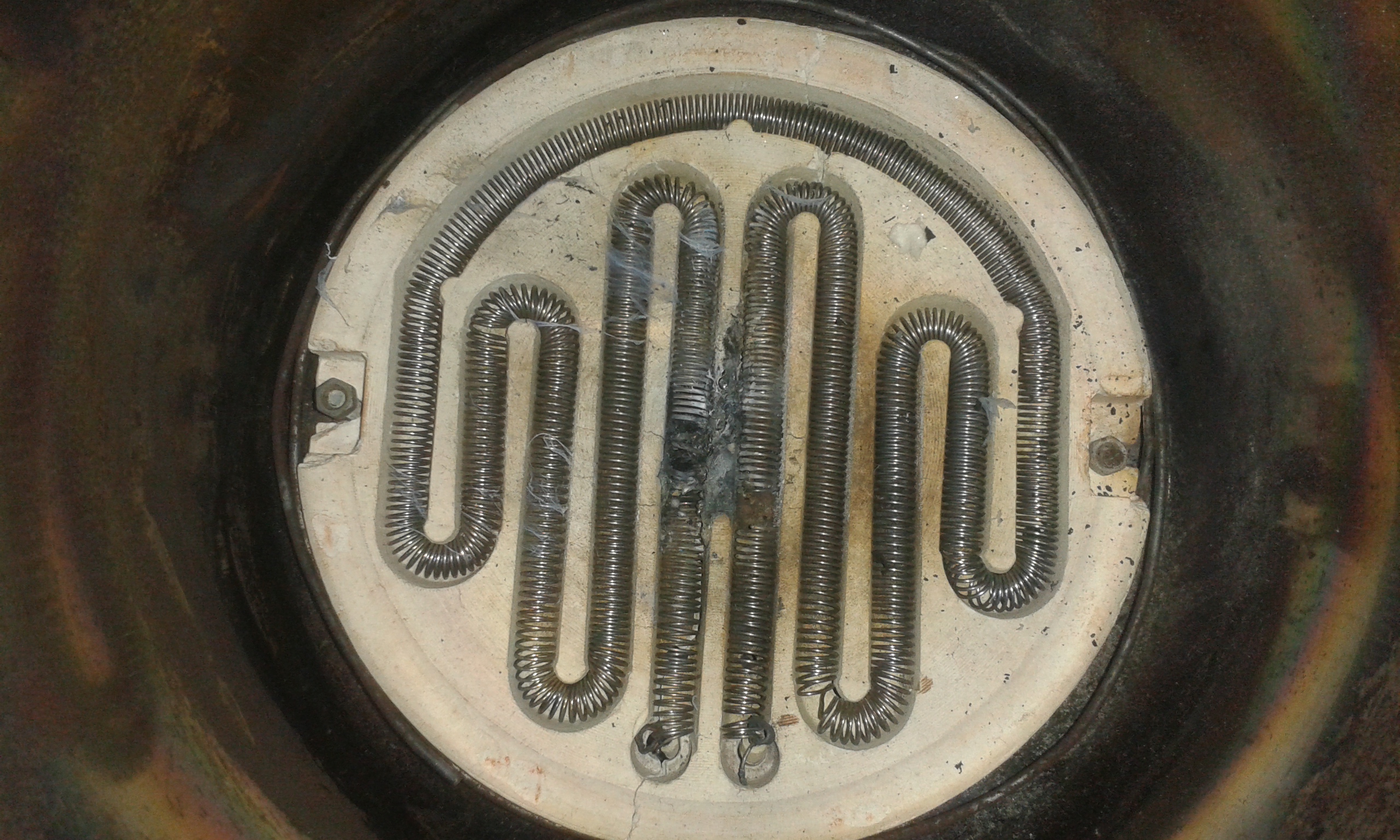

A cross section of the prototype that attempts to implement the above process is shown in the Figure 1 below. There are three chambers contained within each other made up of stainless steel jars redily available in the Indian market as containers to store food items in the kitchens of almost every household. The inner most ‘Waste’ chamber holds the sanitary napkins and is made air tight using a thermally insulated lid. Once this lid is closed there is only one exit termed ‘Pyrolysis gas exit’ in Fig 1. Beneath this waste chamber is a 1 kW electric heater that is controlled on/off by a microprocessor using a PID algorithm (details in electronics section). The electric coil and waste chamber are themselves contained in an insulated chamber named ‘Flame chamber’ in the figure. This flame chamber has an inlet of fresh air beneath the electric heater coil and an exit of combusted flue gases through a chimney. The gas current operates through a natural draft. A thermocouple measures the flue gas temperature at the base of the chimney which forms the feedback to the PID loop.

When the electric coil heats the waste chamber, at around 120-150 deg C, drying of the waste takes place. This stage lasts about 10-20 minutes depending on the waste chamber loading. After this stage, the temperature setpoint of the flue gases is increased to 270 deg C. Pyrolysis gases emerge through the gas exit of the waste chamber and pass over the red hot coils. Air from the air inlet (at the bottom of the device) is also present in this region leading to formation of a flame. The temperatures of the flame are around 800-1000 deg C. The flame partly heats the waste chamber while exiting through the chimney. A temperature of 270 +/- 10 was found empirically to produce a visibly transparent flue gas.

Figure 2 shows the prototype in reality constructed out of SS containers. Figure 3 shows the waste chamber insides and the exit tube.

Electronics

The electronics is composed of a Arduino Nano microcontroller board that drives a Solid State Relay (SSR) on and off to which is attached the 1 kW electric coil. A thermocouple (k-type) is placed at the base of the chimney to sense the temperature of the flue gases. A readymade PID library developed for Arduino is used. Tuning parameters of the PID are yet to be fine tuned to get a foolproof process.