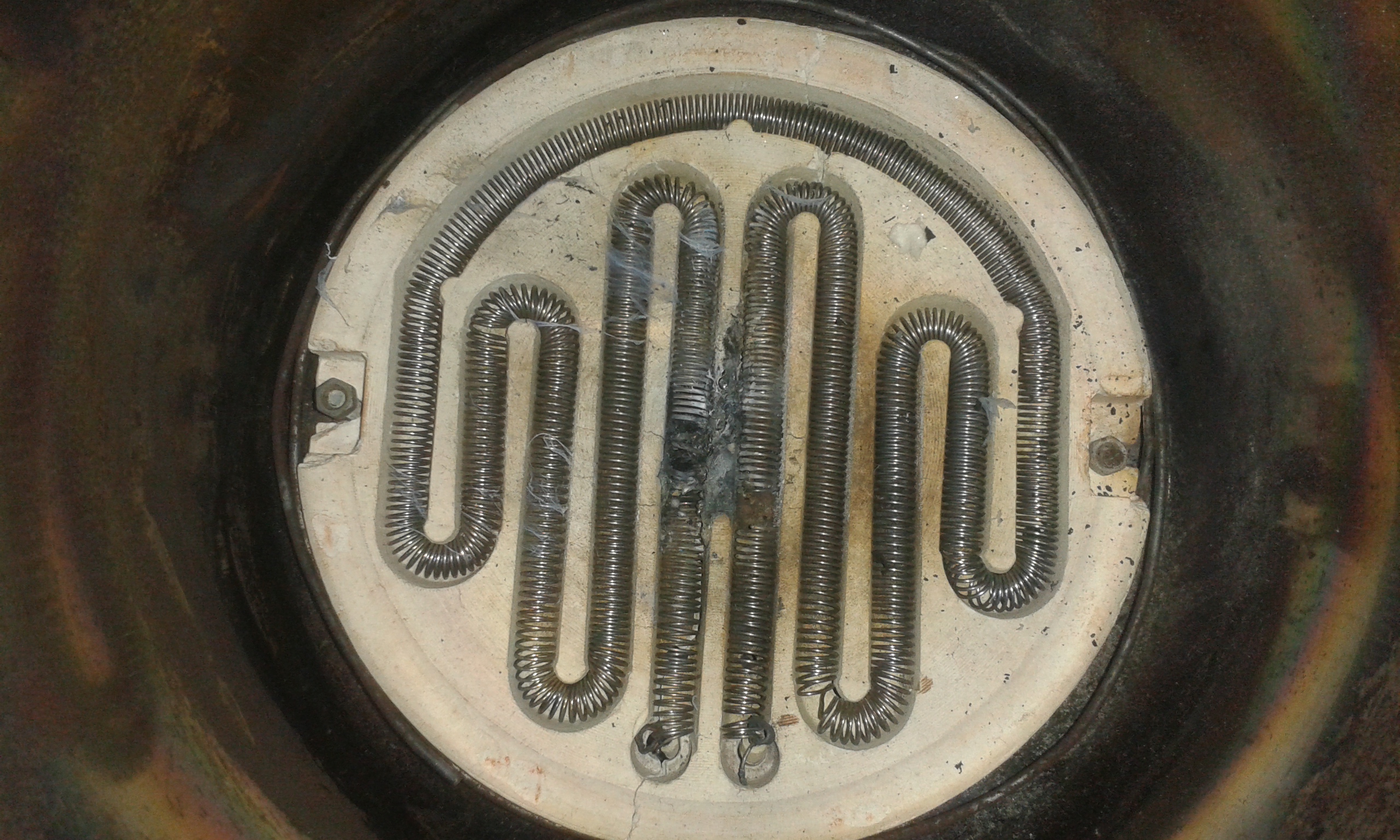

When V1 was brought back to Small Design after the first user trials, the main challenge was how to prevent the coil from getting damaged. Once opened here’s how the burnt coil looked:

Two issues were observed:

- The coil was burnt in the center where the gases exit the waste chamber. This implies that the significant heat of the flames reaches higher than 1000C of the coil limit burning it out.

- Copper wires were used to connect the nichrome coil to the outside. The copper was structurally fine but the contact was broken due to oxidation at the surface of the copper.

Solutions:

- A 2mm plate was placed on the coil that would protect the coil from direct flame. It works so the coil is no more damaged.

- The nichrome wire was salvaged and extended on both the ends to a long wire leads. These leads were insulated with ceramic beads and led directly to interface with the mains neutral and the SSR respectively. This solved issues with bad connectivity.